Page 16

Page 16

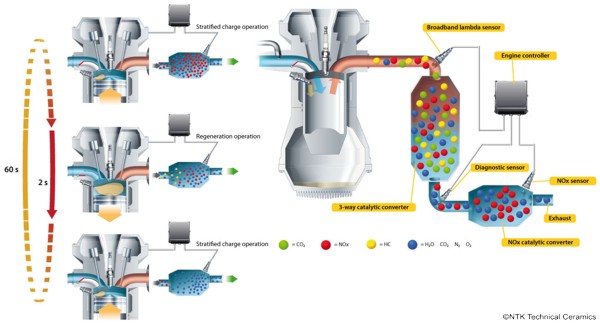

NOX Sensors for Lean Burn Stratified Charge Petrol Engines

In order to increase efficiency of petrol engines, some manufacturers are making engines that operate in the lean range when in partial load, when the engine doesn't operate at maximum power. Gains in fuel consumption are reported up to 25%, although with an increase in complexity of the induction system. VW's FSi system is the canonical example of this system.

As with Diesel exhaust, due to the overly lean mixture in a Lean Burn petrol engine, Oxygen becomes available for reaction with Nitrogen (a normally unreactive gas) because of the high temperatures and pressures. Oxygen will preferentially react with HC (fuel) over N2 (Nitrogen gas) because it takes less energy to do so.

The revised induction system consists of the following main modifications beyond that of a normal setup:

- Variable bore inlet tract with servo flap - this allows the inlet air speed to be regulated to maximise combustion chamber swirl. The same amount of air will be forced to travel faster down a narrower pipe

- Specially shaped piston crown to direct the inlet air and provide maximum turbulence in the lean-burn areas of the cylinders. This means some cylinder volume is leaner than others, hence the term stratified charge, stratified meaning having different layers, a fuel rich centre surrounded by a very lean layer

- Direct injection petrol injector - allows precise timing and progressive injection into the cylinder at any desired point during the piston cycle. Disadvantages include higher operating pressures reducing component life, and inlet tract choking from blow-by gas varnishes and gum. In normal indirect manifold injection this is cleaned away from the passages and inlet valves by the fuel. It is for this reason premium fuels with detergents provide no benefit in a petrol direct injection engine

- NOX catalyser (in addition to a 'normal' 3-way catalyser) stores the nitrogen oxides made during lean-burn operation. During a periodic burn-off phase, every minute or so, the injection system enriches the mixture such that unburned fuel enters the NOx catalyser. Because of the high temperatures in the NOX catalyser, the fuel will burn using the oxygen taken from the NOx, leaving combustion products CO2 H2O and ultimately N2 nitrogen gas - not a pollutant - which is far preferable to NOx.