Page 7

Page 7

Titanium (Titania) Sensors

Titanium Sensors differ in construction from the more common Zirconia type, and offered several advantages to the engine management system. As of 2016 we know of no new vehicles using this sensor type but that may change in the future.

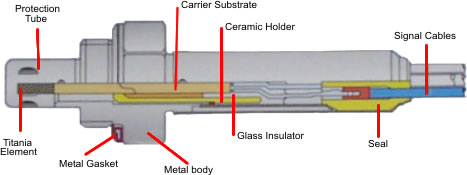

Figure 10 - Cutaway diagram of a titania sensor

Titanium sensors do not generate their own voltage as the Zirconia type do. Instead, the resistance of the sensing element changes in response to the Oxygen present in the exhaust gases. The ECU uses slightly different circuitry to sense the changes which uses a precision voltage reference, and the two types are not interchangeable. However, the output response of the Titania sensor is very similar to the Zirconia. In short, resistance increases when lean, decreases when rich.

There is no need for a pocket of atmospheric reference gas with this type of sensor, hence the absence of a vent. This is important for off-road vehicles where water, mud and debris may contact the exhaust system. The sensor casing can be physically smaller, stronger, and has a faster reaction time than the Zirconia type, which is why it is a functionally superior sensor. However, it is still a narrowband type of sensor.

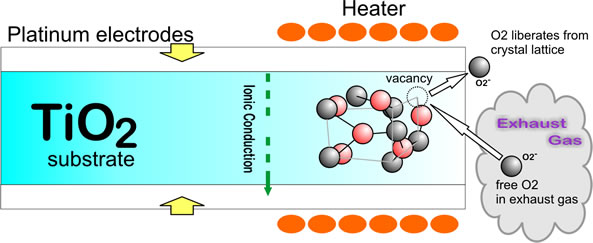

We have been asked how the device can measure oxygen concentration without an atmospheric reference gas for comparison. For this engine control application we are not interested in an absolute value for oxygen concentration, only the step change around stoichiometry. Titanium Dioxide (TiO2, Titanium IV Oxide) exhibits a large resistance step change around stoichiometry. When heated to very high temperatures the TiO2 temporarily loses a small amount of oxygen from its ionic structure, thus making it very slightly conductive. These vacancies can be filled by free O2- ions as found in lean exhaust gas, and the resulting change in conductance can be detected by the ECU circuitry, using a comparator and precision voltage reference. When the mixture becomes rich, there are no free O2- ions to fill the gaps, thus conductivity increases.

Figure 10b - Schematic function of a TiO2 sensor

One reason Titania sensors were initially used is because they are less susceptible to lead poisoning than the Zirconia types. They are, however, more susceptible to anti-freeze poisoning than the Zirconia types. However the other advantages of the sensor (faster response times, more efficient packaging) led some ECU designers to use this type of sensor.

BMW used the Siemens engine management system for the later 3.2 M3's during the 1990s which utilises a Titanium sensor for reasons of being better suited to the high-performance engine ECU, which gives the unit its phenomenal power/weight output. The system was also used on other 6 cylinder BMW's. Two types of sensor are available from Lambdapower each with slightly different mechanical construction, but identical electrical performance. The different types can be distinguished by the different sensor casings - one is smooth, the other stepped.

Vauxhall also used a Siemens ECU during the Nineties, and again for reasons of high performance a Titanium sensor was specified. NGK are the OE manufacturer of all these items because their laboratories developed them, therefore Bosch do not produce a Titanium sensor.

Some Lucas-ECU equipped vehicles also use a Titania sensor, for example V8 Land Rovers, Range Rovers and TVR's.